Before the motor scraper there was the towed scraper – one of the first types of bulk earthmoving equipment to be invented. RICHARD CAMPBELL looks back.

Early ‘Fresno’ type towed scrapers (named after the area in the US where the type originated) were nothing more than simple pans pulled by mules, oxen or horses and dumped by hand – slow and backbreaking work. The man who really got things started, and in fact the father of modern earthmoving, Robert LeTourneau, designed and built the first practical towed scraper in 1923 that was drawn by a track type tractor. The modernisation of earthmoving had begun.

At the height of their popularity in the mid to late 1940s there were some 30 manufacturers in the US alone offering towed scrapers, of both cable and hydraulically operated varieties.

In this stroll down memory lane we will examine some of these offerings starting, as is only appropriate, with LeTourneau.

LeTourneau

The first mass produced LeTourneau scrapers (known as “Carryalls”) were the ‘J’ series, available in six, eight and 12 cubic yard capacities. However World War II was responsible for the two most popular LeTourneau models – the 11 cubic yard Model LS and the 15 cubic yard Model LP, which both had production runs in the thousands and saw service globally.

The model LS in particular was in continuous production from 1942 right through the sale of the company to Westinghouse Air Brake Co (Wabco) in 1953, and it was not until 1963 that the last example rolled off the production line.

LeTourneau had manufacturing plants in Illinois, Georgia, Mississippi and California plus a very important facility in Rydalmere, Australia, which produced many of the machines supplied to New Zealand.

LeTourneau was a preferred supplier to Caterpillar until 1944 and went on to manufacture well over 40 different models of towed scraper before being sold to Westinghouse.

The revamped LeTourneau-Westinghouse company introduced an entirely new range of towed cable scrapers in 1955: the BT, CT and DT. All were very good scrapers with several model CTs being imported into New Zealand. LeTourneau scrapers saw widespread use throughout the country and the occasional example can still be seen operating – some of them 70 years after they were manufactured.

LaPlant-Choate

LeTourneau’s biggest competitor during the 1930s and 1940s, LaPlant-Choate was also a principal supplier to Caterpillar of blades, rippers and scrapers.

The company was based in South Bend, Indiana, and got its start building house removal trailers.

LaPlant-Choate began offering scrapers as early as 1935 and was a pioneer in the field of hydraulic controls. It adopted the trade name of “Carrimor” for its towed scrapers, the most popular models of which included the C-94, C-104, C-108 and the 8.5 cubic yard TW-10 that was built specifically for Caterpillar’s DW-10 tractor.

LaPlant-Choate scrapers featured a bell bottom floor which made them very aggressive loaders, particularly in clay. The trade off was that a special cutting edge had to be fitted to enable any finish work to grade.

LaPlant-Choate was bought out by Allis-Chalmers in 1953 and Allis-Chalmers continued to produce the LaPlant-Choate scrapers (suitably repainted and re-branded) until the early 1960s.

Although not nearly as popular in New Zealand as LeTourneau (mostly due to wartime production restrictions) the odd one or two were imported but in this part of the world they are however quite rare. LaPlant’s hydraulic bulldozers on the other hand were fitted to countless Kiwi Caterpillar D2s and D4s.

Wooldridge

Based in Sunnyvale, California, Mack Wooldridge began his business around the same time as Robert LeTourneau, producing bulldozer blades and then progressing on to scrapers. Wooldridge’s towed scrapers were known as “Terra-Clippers” and were produced in many sizes and models right up to the company’s takeover by Curtiss-Wright in 1958.

Wooldridge scrapers were all cable controlled and the company also manufactured their own cable control units (PCU’s).

Popular models included the TC-142 (17 cubic yards) and the 20 cubic yard OS-200.

Very few Wooldridge scrapers made it to New Zealand. The author would be interested to hear from anyone who still has a Wooldridge scraper in their possession.

Apart from two motor scrapers, none of Wooldridge’s successor’s, Curtiss-Wright, towed scrapers were imported into New Zealand.

Bucyrus-Erie

Better known for their giant mining shovels and draglines, the Bucyrus-Erie company of Milwaukee, Wisconsin, had a thriving business supplying International Harvester with blades, rippers and towed scrapers.

Bucyrus was so good at it that International bought out its earthmoving equipment division in 1953, with all subsequent product being badged as International Harvester.

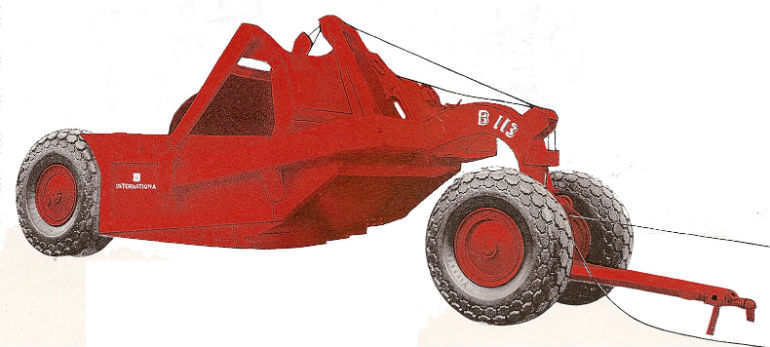

Manufacturing both cable and hydraulically operated two and four wheel scraper types Bucyrus-Erie’s better sellers included the model B-250 (27.5 cubic yards) and B-113 (14 cubic yards).

Some Bucyrus-Erie scrapers were built under licence in New Zealand and marketed under the ‘Hamilton’ brand name.

Isaacson

Another pioneer in the field of towed cable controlled scrapers, Isaacson also manufactured its own cable control units and was another major supplier to International Harvester. Its “Karry-Skraper” range included the models KS-800, KS-1200 and KS-2000.

Hardly any Isaacson scrapers were imported into New Zealand (the author has only ever seen one) however its cable control units (PCUs) and bulldozer blades were widely used on IH TD-14, TD-18 and TD-24 tractors.

Isaacson were bought out by the Pullman Standard Railcar company in 1955. Pullman later divested itself of earthmoving equipment selling the drawings and patents to Washington domiciled Young Manufacturing Corp who continued to market the ‘Karry Skraper’ range virtually unchanged right up until the mid 1970s.

GarWood

GarWood, like LaPlant-Choate, was the victim of an Allis-Chalmers takeover, although a division of the company which manufactures oilfield and truck mounted recovery winches still exists.

There was no mistaking a GarWood scraper from a distance as they had a unique profile and quite a few were imported into New Zealand.

Both hydraulic and cable controlled models were offered but, in New Zealand, the most popular types were the cable operated models GW-624 (18 cubic yards) and the 12 cubic yard GW-612.

GarWood scrapers had disappeared by 1956 as Allis-Chalmers elected to produce the recently acquired LaPlant-Choate designs instead.

Caterpillar

Cat was quite a late starter in the towed scraper business, not introducing their first scraper (the No.70) until 1946. However, once established, Caterpillar pretty much swept away the competition apart from LeTourneau.

Caterpillar offered a wide range of well built and easy to maintain towed scrapers which, apart from the 3.5 cubic yard No.40, were all cable controlled.

Initially Caterpillar scrapers had curved (bell-shaped) bowl floors similar to LaPlant-Choate’s but a redesign in 1952 eliminated this feature and substituted the more common flat floor. Another revamp in 1958 introduced the “low bowl” concept that was designed to promote easier, faster loading. The low-bowl principal was also applied to their range of cable controlled motor scrapers, the DW15, DW20 and DW21.

Caterpillar’s most popular models in New Zealand included the No.40, No.60, No.70, No.435 (which replaced the No.70), No.80 and the No.463 (which replaced the No.80).

Caterpillar’s largest offering, the 27 cubic yard No.491 did not make it to New Zealand shores.

Many Cat towed scrapers can still be found operating today, some converted to hydraulic operation, testimony to the soundness of their design.

Heil

Based in Milwaukee, Wisconsin, Heil was a major supplier of equipment and attachments to International Harvester.

It began developing a range of cable controlled scrapers prior to World War II but were forced to suspend production of these due to war constraints. During this period they also began development of their own range of motor scrapers.

International Harvester bought the construction division of Heil in 1952 to gain their motor scraper technology. International didn’t need another towed scraper line (they already had Bucyrus-Erie and Isaacson) so the Heil designs and patents were sold to the Oliver Corporation in 1955.

The original Heil designs have had quite a few name badges applied since Heil first offered them: Oliver, Britstand, Allied and Hewco, to name a few.

Genuine Heil scrapers are now quite rare but the occasional example can still be found. Most have been converted to hydraulic operation.

The Heil company still exists today as a very successful builder of dump truck bodies and refuse collection equipment.

Other American manufacturers

Do the names Slusser-McLean, Kay-Brunner, Baker, Adams, Be-Ge or Austin-Western stir any memories?

All of these manufacturers mentioned mass-produced towed scrapers from the 1930s onwards, some producing scrapers well into the 1960s.

Add to that list more contemporary producers such as Southwest, Ateco, Rome and Cepco and you can gauge just how important and diverse the towed scraper business was.

However, very few, if any, of these brands have moved New Zealand soil.

Vickers-Onions

The Onions division of Vickers located in Scotswood, Newcastle, England, got into the scraper business by copying a couple of LeTourneau’s designs. Subsequent offerings from Onions were all original and very popular in New Zealand.

Extremely rugged in construction, the scrapers featured a low centre of gravity and a very convenient counterbalanced drawbar, which made them easy to connect to the towing tractor. Almost all of Vickers-Onions scrapers were cable controlled but they did venture into hydraulics with a small six cubic yard offering which was often seen behind Ford ‘County’ series tractors.

The most popular models were the six cubic yard Model O6-8, 12 cubic yard Model 12-16, and the 16 cubic yard model 15-21, which was especially popular in New Zealand. Many of these old girls can still be found lying around.

Due to their design they can be easily converted from cable to hydraulic operation.

The Vickers Onions scraper line ceased production in the early 1960s.

Kokudo

In Japan during the 1960s the towed scraper was very popular indeed. The short hauls and soft terrain of the Japanese landscape was well suited to the track type tractor and towed scraper combination, which could work effectively where motor scrapers could not.

Japanese manufacturer Kokudo filled a major gap in the domestic market by producing hydraulically operated scrapers broadly based on Caterpillar and Rome designs.

A considerable number of these scrapers have found their way here and are actively involved in reshaping the New Zealand landscape. Kokudo scrapers are sturdily constructed and perform well under local conditions.

These scrapers have also been supplied to, and marketed under, the Komatsu brand name.

Britstand

Manufactured in Sydney, Australia, the Britstand (British Standard Equipment) company built scrapers under license from the American Heil Corp.

These were cable controlled designs, although, through the passing of years, some have also been converted to hydraulic operation.

A fair number were imported into New Zealand during the early 1950s, although a working example may be a little difficult to find these days.

Britstand’s biggest seller in New Zealand was the eight cubic yard OC-8.

Birtley

The Birtley company of Durham, England, produced the Caterpillar No.60, No.70 and No.80 cable controlled scrapers under licence for sale in Europe and export to the colonies.

They also manufactured the No.15 and No.20 trailing scrapers for the DW15 and DW20. These were identical to the Caterpillar produced product apart from the name “Birtley” on the bowl side sheets. A substantial number of these were imported into New Zealand.

The Birtley name disappeared after Caterpillar took over production in the UK in 1963.

Wright

Wright, Boag & Head were a South African company who, like Birtley, produced Caterpillar equipment under license.

While the Birtley name basically vanished, Wright went from strength to strength, manufacturing a very wide range of Caterpillar equipment for South African domestic consumption.

Identical to the US built product, a few examples of Wright’s towed scrapers have made their way to New Zealand, most notably the No.40 and No.60.

Hewco

The Huntly Engineering & Welding Company (Hewco) built a number of towed scrapers that closely resembled the American Heil/Britstand model OC-6.

While exact production numbers are not known it is estimated that there were at least 10 and possibly 12 produced. These were sold to contractors throughout the North Island.

One of the bowls was used as the basis of New Zealand’s only indigenous motor scraper, the Hewco Twin-Six.

Hewco ceased production of towed scrapers in the early 1960s.

Cable Price

Manufactured at Gracefield, Wellington, by A&G Price, the model CPC-6 was not an indigenous design but in fact built under license from Sterling of Great Britain.

The CPC-6 was a six cubic yard all hydraulically controlled towed scraper, ideally suited for operation behind an Allis-Chalmers HD-6 or similar sized track type tractor.

Exact production figures are unknown but estimated to be in the region of 20 machines.

Hamilton

As mentioned earlier, CWF Hamilton produced the American Bucyrus-Erie type S-68 scraper under the Hamilton brand name. These differed from US built items by using standard truck tyres for flotation rather than the wider base tyres of their American cousins.

Not highly regarded by contractors, they were hard to load and unnecessarily complicated to reeve.

Total production of this model is estimated at between 10-15 examples.

So, forget all those fancy ADTs and hydraulic excavators – the tractor towed scraper is still the cheapest way to move bulk dirt over a short distance. In the hands of a skilled operator a single track type tractor with towed scraper can dig, haul and spread without the need for any other ancillary equipment. It can even compact the fill by running over the spread material on its way to and from the cut.

Scrapers – the “funnest” way to move dirt!

For the modeller

For collectors of earthmoving equipment there is not a great deal of choice when it comes to towed scrapers.

Spec Cast manufacture a very good model of the LeTourneau type LP towed scraper in 1:50th scale and there is also a horrendously expensive 1:25th scale model of the same scraper produced by Sherwood.

Caterpillar collectors have very slim pickings with only the recent First Gear release of a 1:25th scale No.491 being readily available.

EMD Models of Europe produce models to 1:50th scale of the Garwood 615, Caterpillar 463 and Bucyrus-Erie S-250 scrapers but these are expensive limited run offerings.

Regrettably, to the best of the author’s knowledge, there are no other models of towed scraper currently available.