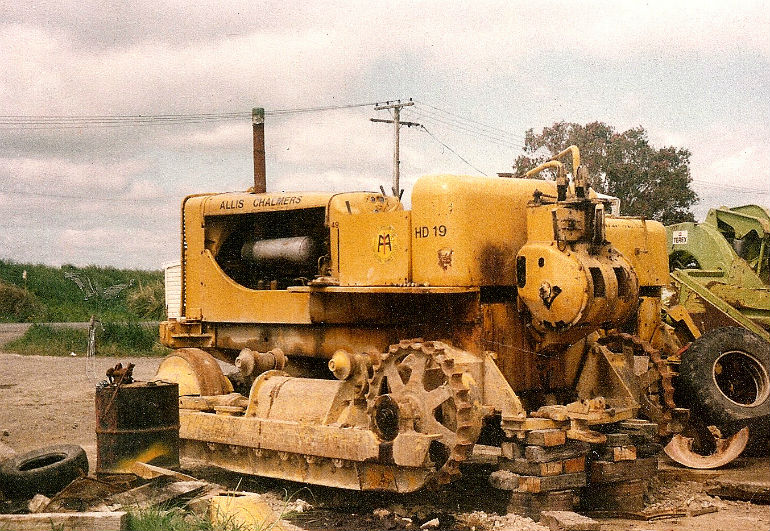

Allis-Chalmers was the first heavy machinery builder to enter the big track-type tractor development race immediately following World War II. Richard Campbell looks at its model HD-19H.

Up until World War II, the largest track type tractor that Allis-Chalmers had produced was the 14 ton, 126 horsepower HD-14C. This machine had been well received and was the first track type tractor to feature a torque converter, but contractors were calling for something bigger, and Allis-Chalmers certainly delivered the goods with the HD-19H.

An all-new design, the HD-19H incorporated all of the existing proven Allis-Chalmers features and introduced a few more for good measure.

The ‘H’ in the designation stood for hydromatic, a reference to the torque converter in the transmission, which was a pretty big deal in the 1940s. The term persisted into the early 1950s for all Allis-Chalmers tractors with torque converter drive.

At the time the HD-19H was introduced, General Motors’ Detroit Diesel division had a deal with Allis-Chalmers and the entire Allis-Chalmers track type tractor range was powered with GM diesels (as were a lot of other Allis-Chalmers manufactured products).

Under the bonnet of the HD-19H was a 130 horsepower General Motors model 6-71 inline, six-cylinder diesel with roots blower. This was connected via torque converter to a two-speed manual transmission with one reverse gear. A high and low range was available within each gear selection allowing the HD-19H to move around at up to seven miles an hour. Double reduction final drives finished off the drive train.

Steering was by conventional steering clutches and contracting band brakes that were hydraulically boosted – a first for an Allis-Chalmers track type tractor.

The operator had a very clean workspace for the day, with Allis-Chalmers taking a great deal of effort to tidy up the operator environment. Control levers and pedals were grouped for ease of operation and the gearshift lever was placed closer to the operator to eliminate reaching. A full compliment of gauges was clustered on a slightly angled panel for easier viewing and the operator was provided with a deeply padded full width bench type seat with arm rests.

The engine bonnet was tapered unevenly to provide a better forward view to the right, a practice later adopted by nearly all the large track type tractor manufacturers. As such, the HD-19H was one of the first modern post-war crawler tractors to consider the operator and make the machine easier to operate.

Of conventional layout, the Allis-Chalmers HD-19H had a six roller track frame with two carrier rollers and was normally supplied on 24 inch track shoes, although other optional width shoes could be specified.

Allis-Chalmers had an industry reputation for rugged construction and the HD-19 was no exception.

Allis-Chalmers did not begin to manufacture its own attachments until the early 1960s so blades and other ancilliary equipment for the HD-19H were supplied by outside vendors such as LeTourneau, Baker, Carco and GarWood. Most New Zealand delivered machines were put into service equipped for towing scrapers outfitted with either a GarWood or LeTourneau double drum PCU.

The HD-19H was manufactured for four years – 1947 to 1950 – during which time some 2600 examples were produced.

It was replaced by the similar sized but heavier and more powerful HD-20H, which will be the subject of a future Contractor article.

The New Zealand connection

Very few Allis-Chalmers HD-19s made it to New Zealand shores, probably fewer than 10 but the actual number is not known. This is probably due to the fact that there were a great deal of war-surplus machines available at that time and new machines were expensive.

The most notable operators were Dryden Construction and New Zealand Roadmakers (both of Auckland) who featured these machines in their respective fleets.

These were used primarily in roading and subdivision work, construction of the Auckland motorway and the Stage 1 earthworks of Mangere airport.

Latterly the late Ian Martin of Ngatea had a well kept example which was still operating well into the 1980s.

The author is unsure if any still survive intact.

Brief Specifications – Allis Chalmers HD-19H

Engine: General Motors model 6-71, 6-cylinder, inline diesel with roots blower rated at 130 horsepower.

Clutch: 16” single plate.

Torque Converter: Twin-Disc, 3-stage.

Transmission: Manual, built by Allis-Chalmers with two forward and one reverse range, high/low available in each range.

Brakes: Contracting band, power assisted.

Track Frame: Six roller with two carrier rollers per side.

Standard Tracks: 37 section with 24 inch single grouser shoes.

Operating Weight: 21 tons (bare), approximately 23 tons with blade and PCU.