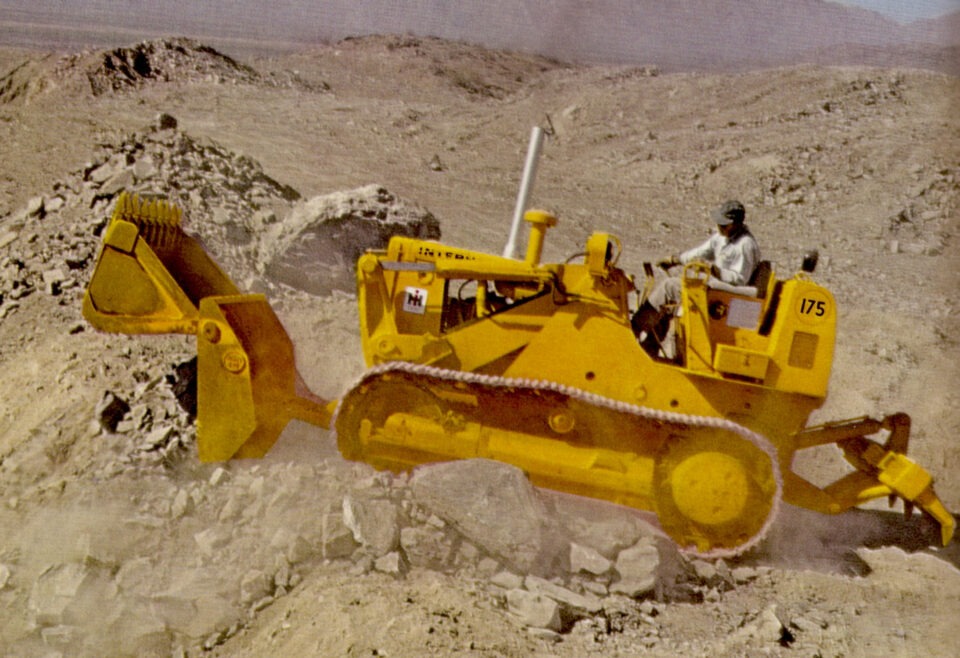

Originally introduced in 1963, the International model 175 was broadly based on the company’s model TD-15B track-type tractor. By Richard Campbell.

One of a quartet of totally integrated track-type loaders to be offered by International Harvester that year (the others were the 100, 150 and 250), the model 175 replaced the former TD-15-151 track-type tractor fitted with a Drott front-end loader attachment.

Prior to the introduction of the model 175, International TD-15-151s were supplied as bare tractors to Drott Manufacturing, a major attachment supplier to International-Harvester, that then built and added the loader frame, arms, hydraulics, counterweight, and bucket to the machine transforming it into a dedicated track-type loader.

Drott would also replace the single grouser track shoes if required with double or triple grouser shoes at customer request.

One of Drott’s biggest claims to fame was the invention of the four-in-one loader bucket, an incredibly useful tool still offered today.

Another one of Drott’s inventions was the “Hydro-Spring”, a device that cushioned shock loads on the hydraulic system and was in widespread use on Internationals track loaders throughout the 50s, 60s and 70s.

By the early 1960s however, International realised that its current track-type loaders were somewhat of a compromise, and with other manufacturers introducing their own dedicated track loaders, the decision was taken by IH management to build an integrated track loader from the ground up.

Utilising the engine and torque converter/transmission assembly from its model TD-15B dozer, a completely new machine was constructed with an integrated loader tower, rigid track frame, planetary final drives, and an extra hydraulic valve with diverter to operate a four-in-one bucket or ripper (depending on customer requirements).

The new model 175 weighed approximately 14 tons and was fitted with a one and three-quarter cubic yard bucket, with a Drott four-in-one bucket offered as an option (along with the extra counterweight required).

The new model 175 was powered by an International DT-407 six-cylinder turbocharged diesel engine, which produced 115 flywheel horsepower.

One of the features carried over from the previous Drott designs International had formerly offered was the Z-bar loader linkage, which gave the machine exceptional breakout force at ground level as it exerted a very strong prying action.

Unlike some of its contemporaries, the model 175’s operator was very well placed on the machine and not buried in a ‘tub’ from which it was difficult to enter and exit.

In fact, the 175 had an almost walk-through deck and good visibility to the rear.

The new model 175 loader was very well received by the contracting market and sold exceptionally well. International Harvester had a winner on its hands.

During 1966, an upgraded version of the model 175 was introduced, the model 175B.

Principal differences from the initial production model included a slight horsepower increase from 115 to 120 horsepower, modifications to the carrier roller mountings to strengthen them and an increase in standard bucket size from one and three-quarters to two cubic yards.

The range of optional attachments was also expanded to include an angle blade, logging forks and a stone grapple.

Again, the machine sold in quantity and was used in all sorts of applications.

International Harvester launched the final version of the machine, the model 175C loader in 1972.

This updated version featured an all-new engine, the 6-cylinder, turbocharged, International DT-466, which was rated at 140 flywheel horsepower.

This change brought the machine into parts commonality with other tractors in International-Harvester’s ‘Pay Line’ range as the DT-466 engine was also used in the TD-15C bulldozer, 412 elevating scraper and was the rear engine of both the 433 and 444 motor scrapers.

Changes were also made to the undercarriage, making these components even stronger, and Occupational Safety and Health Administration (OSHA) mandated rollover protective structure (ROPS) mountings were also incorporated into the chassis to make the machine safety compliant.

In this form, the model 175C track loader remained in production until International-Harvester were taken over by Dresser in 1982.

Dresser did not persist with the manufacture of this type as demand for track-type loaders was waning due to the increasing acceptance of the hydraulic excavator, and so the model 175C was finally withdrawn from production.

All time production of the International 175 exceeded 13,000 examples with the only real competition being the Caterpillar 955.

The 175 was especially popular in demolition and logging applications where it could take the brunt of the harsh operating environments.

A New Zealand connection

All three versions of the International 175 sold well in New Zealand, and to all sectors of the contracting, forestry, and demolition industries.

It is estimated that over 250 machines were imported into NZ during the time the machine was in production (1963-1982).

For the model collector

The International 175C has been reproduced in model form in two different scales, 1:50 and 1:25.

Both models, which were manufactured by diecast maker First Gear, are exceptionally well crafted and detailed, having many operating features and proper triple grouser metal tracks.

The 1:25 scale version in particular is of museum quality and was released in a limited run of three versions – general contracting (with four-in-one bucket and ripper), demolition (with special bucket, guarding and winch), and an all-red version in the colours of the U.S.Forest Service.

Unfortunately, these models which were originally released in 2007, are becoming quite hard to find, so if you get the opportunity to acquire one, do so as you will not be disappointed.

Brief Specifications

Engine: International DT-466, 6-cylinder, inline turbocharged diesel rated at 140 flywheel horsepower at 2400 rpm.

Transmission: International full powershift countershaft type transmission with two forward and two reverse ranges plus a high/low splitter giving 4 speeds in either direction.

Steering: Planetary type with multiple disc brakes, oil cooled.

Track Frame: Six-roller.

Tracks: 15-inch, triple gouser.

Standard Bucket: Two cubic yard, general purpose.

Length: 16’ 4”.

Width: 7’ 2”.

Op.Weight: 14.5 tons