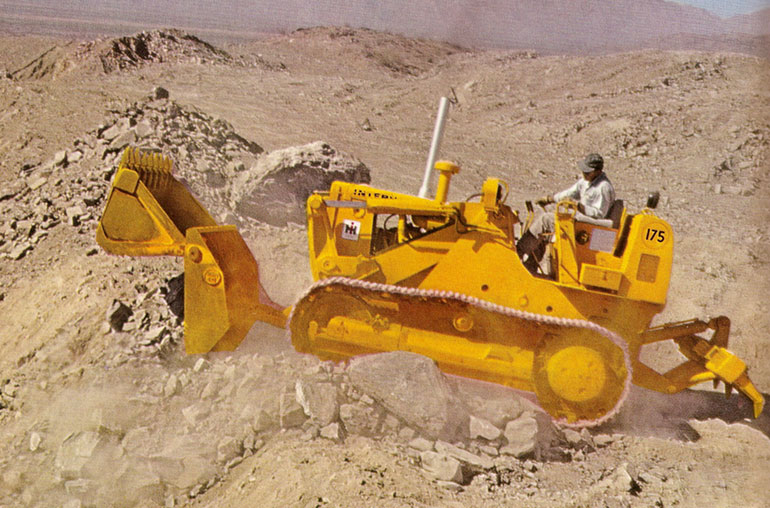

Introduced in 1963, the Model 175 was one of a quartet of totally integrated track type loaders to be offered by International Harvester (the others were the 100, 150 and 250).

THE MODEL 175 replaced the former TD-14 and TD-15-151 track type tractors that were supplied bare to Drott Manufacturing, which then built and added the loader frame, arms, hydraulics, counterweight and bucket to the machine transforming it into a dedicated track type loader.

Drott would also replace the single grouser track shoes if required with double or triple grouser shoes at customer request.

Drott was strongly aligned with International as a business partner and its biggest claim to fame was the invention of the 4-in-1 loader bucket, an incredibly useful tool still offered today by many manufacturers.

Another of Drott’s inventions was the ‘Hydro-Spring’, a device which cushioned shock loads on the hydraulic system and was in widespread use on International’s track loaders throughout the 50s, 60s and 70s.

International Harvester realised however that these machines, like a number of other track loaders, were pretty much a compromise so the decision was taken to build a dedicated track loader from the ground up.

Utilising the engine and torque converter/transmission assembly from its model TD-15B dozer, a completely new machine was constructed with an integrated loader tower, rigid track frame and planetary final drives.

With an operating weight of approximately 14 tons and carrying a 1¾ cubic yard bucket, the new model 175 was powered by an International DT407 six cylinder diesel putting out 115 flywheel horsepower.

One of the features carried over from previous Drott designs was the Z-bar loader linkage, which gave the machine exceptional breakout force at ground level as it exerted a very strong prying action.

Unlike a lot of other track loaders of the period, the operator was very well placed on the machine and not buried in a ‘tub’ from which it was difficult to enter and exit. In fact the 175 had an almost walk-through deck and good visibility to the rear.

Supplied standard with an extra third hydraulic valve, the 175 could be fitted with a 4-in-1 bucket, ripper or both (with a diverter valve) if the customer required it.

The 175 was very well received by the contracting market and sold exceptionally well.

International Harvester had a winner on its hands.

During 1966, an upgraded version was introduced, the model 175B.

This differed from the initial production version by having a slight horsepower increase from 115 to 120 horsepower, modifications to the carrier roller mountings and an increase in standard bucket size from 1¾ to two cubic yards.

The range of optional attachments also expanded to include an angle blade, logging forks and a stone grapple.

Again, the machine sold in quantity and was used in all sorts of applications.

International Harvester launched the final version of the machine, the model 175C in 1972.

Featuring an all-new engine, the six-cylinder IH DT466, was rated at 140 flywheel horsepower.

This change brought the machine into parts commonality with other tractors in International-Harvester’s ‘Pay Line’ range as the DT466 engine was also used in the TD-15 dozer, 412 elevating scraper and was the rear engine of both the 433 and 444 motor scrapers.

Changes were made to the undercarriage, making these components stronger, and OSHA required ROPS mountings were also incorporated into the chassis to make the machine safety compliant.

In this form the 175C remained in production until International was taken over by Dresser in 1982.

Dresser did not persist too long with manufacture of the type as demand for track type loaders was waning and it was finally withdrawn from production.

All time production of the International 175 exceeded 13,000 examples with the only real competition to the type coming from the Caterpillar 955.

The 175 was especially popular in demolition and logging applications where it could take all the punishment dished out to it in these harsh operating environments.

Isolated examples can still be found working.

The 175 pay loader described

We will look at the 175B model that was produced in the largest quantity (over 6500 examples).

Power was provided by a six-cylinder, International model DT407 turbocharged diesel engine putting out 120 flywheel horsepower.

This in turn was attached to a single stage torque converter and two-speed powershift transmission with manually selected high and low speed ranges giving an effective four speeds forward and reverse.

Steering was effected by International’s patented planetary, multiple disc brake steering system which allowed both tracks to be powered at all times. This unit was oil cooled to prolong the life of the discs.

Power was transmitted from the clutches to the planetary final drives which could be serviced without breaking the tracks, and were isolated from shock loads.

A monolithic welded steel tub held the engine, transmission and drive train and also formed the foundation of the loader tower.

Track frames were rigidly connected to the chassis structure by two heavy cross members.

Standard track frame was a 6-roller type with 39-section sealed track and 15’ triple grouser track shoes. Track tension adjustment was via a grease-filled hydraulic cylinder mounted in each track frame.

The operator sat high and had an excellent view of the work area and tools. Floor panels were flat and allowed an almost walk through environment. A centrally placed instrument panel was well provided with gauges to monitor the machine’s performance.

As mentioned previously, the loader mechanism was of the Z-bar type. Two hydraulic cylinders provided the lift and two cylinders furnished the crowd/dump force.

Automatic bucket positioning was standard, and when fitted with the optional 4-in-1 bucket, a rod on top of the left tilt cylinder gave an optical reference as to what mode the bucket was in.

Optional equipment included a cab, heater, lighting package, different sized track shoes, radial or parallel action ripper and a winch.

The New Zealand connection

As could be expected, the International 175 sold very well here to all sectors of the contracting and forestry industries, and all three versions of the machine (175, 175B and 175C) were imported. It is believed that over 250 machines came into NZ during the time the machine was manufactured (1962-1982).

With the rise of the hydraulic excavator came the demise of the track type loader and examples of the 175 are not a common sight these days.

It is to be hoped that someone will save one for preservation.

For the diecast model collector

For a change, I am pleased to be able to report that there are two excellent models of International’s 175

track loader available and these both represent the model 175C version – one to 1:50 and the other to 1:25 scale.

Manufactured by First Gear, they were released in 2007 and are still generally available.

The 1:25 scale example in particular is museum quality and available in three versions – general contracting (with ripper), demolition (with special demolition bucket and winch) and an example as used by the US Fire Service, painted in red.

Either large or small scale would make an ideal addition to any serious collection.