As a result of its experience manufacturing tanks during WWII, Vickers-Armstrong of Newcastle, England decided to build a track-type tractor to take on the Americans. BY RICHARD CAMPBELL

A successful product would be a boost to Britain’s war ravaged economy and also stem the flow of imported tractors which used up valuable overseas funds.

Design studies began in 1946 and by 1950 a prototype had been assembled and tested to the satisfaction of the engineers although actual production of the Vickers model VR180 (soon to be known as the ‘Vigor’) did not commence until 1952.

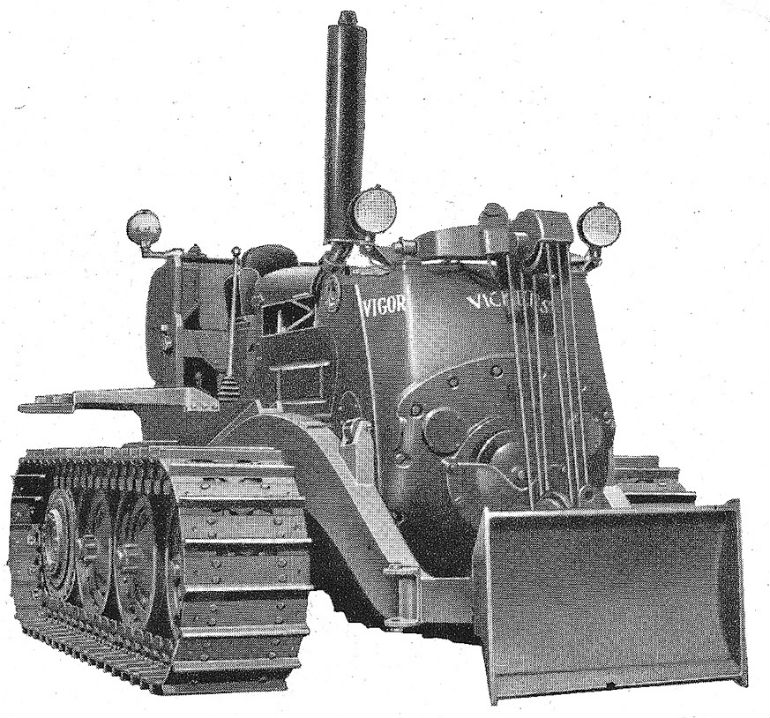

The design of the tractor was unique – the VR180 resembled no other track-type tractor available anywhere in the world at that time. The machine was also very innovative in a number of areas, displaying some very advanced ideas for the time.

All the components were of British design and manufacture including the matched line of attachments – blades, cable control units, winches, hydraulic controls, towed scrapers, etc.

Considered to be a D8-sized tractor in its day, the Vickers Vigor was powered by a Rolls-Royce C6SFL, six-cylinder, supercharged, inline diesel engine, rated at approx 160 horsepower at 1800 rpm. A fairly rugged and reliable engine, the C6SFL featured dry sump lubrication, direct electric starting and a viscous silicone torsional damper along with a fair quantity of aluminium castings in place of cast iron. The dry sump feature allowed constant full pressure lubrication of all the vital engine internals even at extreme operating angles. Euclid (Great Britain) also favored this powerplant and utilised it in a number of its machines.

Coupled to the diesel was a six-speed constant mesh transmission of Vickers’ own design, driven through an 18 inch single plate Borg & Beck clutch.

Compared to its contemporaries, who could make about 5.5 miles per hour in top gear, the Vigor was a racehorse, with a top speed of almost 10mph.

By far the most radical feature of the Vigor was its undercarriage. This was heavily influenced by the company’s experience in tank design, and incorporated a sprocket and three idler-sized road wheels per side with no carrier rollers.

These units were all fully articulated and allowed the Vigor to literally envelop obstacles in its path without lifting track off the ground and consequently losing traction. A comparison could be drawn in the design of Caterpillar’s bottom rollers on its hi-drive track type tractors, which operate in a similar ground hugging fashion.

The entire undercarriage was isolation mounted via rubber bushings to absorb shock including the sprockets.

Normal track chain would, of course, not fit the Vigor due to the unique design, so Vickers made its own. This was a rather complicated affair and had quite a few more parts than a usual track assembly does. Included were rubber washers in the link bushes to exclude dirt.

The tractor was manufactured in two sections – a front hull, which contained the engine and clutch, and a rear hull, which held the transmission and final drives. Literature of the day stated that the machine could be separated for maintenance by two trained technicians in two hours.

For the operator, the Vigor had a wide, comfortable seat; great visibility and a very clutter-free deck. A foot throttle/decelerator was also a feature of the Vigor.

As production progressed several options were made available to purchasers. These included a torque converter drive option and replacement of the Rolls-Royce engine with a Cummins model NT6-BI, six-cylinder, turbocharged diesel, rated at 210 horsepower. Most purchasers preferred the Rolls-Royce.

The VR180 Vigor was manufactured up until 1961 when mounting development costs, indifferent performance, declining sales and the American juggernaught finally laid the machine to rest. Vickers attempted a comeback with a somewhat refined version of the Vigor known as the VR110 Vikon but just over 20 were produced before these also went the way of the Vigor.

So what went wrong?

The Vickers VR180 Vigor was sold throughout the British Commonwealth and also exported to South America and the African continent. It failed to penetrate the US market due to the overwhelming dominance of Caterpillar, Allis-Chalmers and International Harvester.

While the Vigor was basically mechanically reliable it also had a number of very annoying faults. It was not a stable bulldozing platform and finishing blade work was extremely difficult due to the design of the undercarriage and how the blade was attached to the tractor. Although fast and a good scraper tow tractor, the Vigor loved to throw its tracks. This was due to rapid deterioration of the rubber seals in the track bushes allowing it to snake badly at speed, even when comparatively new – very disconcerting indeed.

In certain applications the individual bogey units could easily turn over on themselves in uneven terrain, also resulting in a thrown track. The machine is also known to have parted company with itself at the hull joint.

These problems were never satisfactorily addressed by the manufacturer and fewer prospective buyers were willing to take a chance on the machine, no matter how fast or productive it may have been.

The New Zealand connection.

Twenty-six Vickers VR180 Vigors were imported into New Zealand by the local dealer, Dominion Motors Corp (later Domtrac). The bulk of these machines were imported for the Ministry of Works, which used them extensively in the Wellington region on the Rongotai Airport project, Porirua state housing project and Seatoun state housing projects.

Some found their way on to central North Island hydro projects while others were ‘loaned’ to Clifton Colliers for stripping operations in the Northern Waikato.

At least four Vigors were in private ownership: GR Craw Contracting of Auckland had three while KJ McMillan had one.

The author knows of two preserved examples, both in the North Island.

Brief Specifications – Vickers VR180 Vigor

Engine: Rolls-Royce C6SFL, six-cylinder, inline, supercharged diesel

Clutch: Borg & Beck 18” single plate

Transmission: Vickers three-speed constant mesh with high/low splitter

Top Speed: 9.7 mph

Steering: Conventional clutch and brake

Brakes: Contracting band

Tracks: 51 section, sealed

Std.Track Shoe: 22”

Gauge: 80”

Overall Length: 14’ 8” (bare)

Overall Width: 8’ 6” (bare)

Overall Height: 9’ 11”

Operating Weight: 16 tons (bare)