Allis-Chalmers led the charge for a bigger, higher horsepower track type tractor following World War Two. The resulting model HD-19 was a breakthrough in many ways and was the foundation on which the later, highly successful model HD-21 was based. By RICHARD CAMPBELL

We first took a look at the Allis-Chalmers HD-19 back in 2009.

Since that time, much more information has come to light, so it is high time we re-examined this machine.

On it’s introduction in 1947, the HD-19 was called the HD-19H.

The H stood for “Hydromotive”, referring to the fact that the tractor was equipped with a torque converter.

It was not the first track type tractor that Allis-Chalmers had manufactured with a torque converter, that honour belonging to its model HD-14 which came out in 1946 and was the first track type tractor of any manufacturer to have this device.

The HD-19 supplanted the HD-14 in production and pretty soon after the “H” was dropped from the end of the machines HD-19H designation, the tractor being simply known as the HD-19.

Allis-Chalmers had established a strong relationship with General Motors for the supply of diesel engines.

This relationship went back as far as 1938 when various types were being tested in some of Allis-Chalmers’ gasoline powered machines with varying degrees of success.

When the “HD” series of machines began to appear, these were all powered by General Motors 71 series engines – GM 2-71 in the HD-5, GM 3-71 in the HD-7, GM 4-71 in the HD-10 and HD-9, and the GM 6-71 in the HD-14, HD-15 and the new HD-19.

For Allis-Chalmers it was a match made in heaven as the two-cycle GM engines were powerful and more importantly, reliable.

As the GM engines had been extensively used by the US armed forces, there was no shortage of people who knew how to work on them and they were simple, and relatively cheap to overhaul.

Allis-Chalmers chose the GM 6-71 for the HD-19.

This delivered 163 flywheel horsepower at a rated engine speed of 1750 rpm and featured direct electric starting.

Connected directly to the engines flywheel was a 17” dry type master clutch manufactured by Lipe-Rollway.

Beyond the clutch was the hydraulic torque converter which used diesel fuel, not oil, to help multiply the engines lugging ability.

These types of converters were known as ‘diesel charge torque converters’ and many manufacturers ended up using them, including Caterpillar.

One of the added benefits of the torque converter (apart from its lugging ability), was it was almost impossible to stall, cushioned gear changing shock, and in a lot of cases, reduced the number of gear changes required during loading, dozing etc..

A great gadget indeed that is still in widespread use today.

On the HD-19, the torque converter was located directly under the operator’s floorboards making it easy to remove if maintenance was required.

Attached to the other end of the converter was the HD-19’s transmission.

While most track type tractors of the day had five or six speed gearboxes, the HD-19’s was a very simple affair with two speeds forward and one reverse.

It did not need to be any more complicated as the torque converter compensated for all the speed ratios in between.

Top speed of the tractor was a respectable 7 mph.

Steering

Another of Allis-Chalmers’ innovations was its continuing development of better tractor steering.

The HD-19 was steered in the conventional manner for tractors of the period, by steering clutch and brake.

However, the steering clutches featured a hydraulic booster which reduced the effort required to engage them to practically zero.

Brake bands were of the contracting band type, self energizing, and could be easily adjusted.

Allis-Chalmers well understood the need for easy maintenance and to this end the entire steering clutch/brake band assembly for either track could be removed from the tractors main case as a unit by removing the fuel tank and one cover plate.

The Track Frame

The HD-19’s chassis was a semi-‘H’ section box frame welded together across the front.

This in turn was bolted to the tractor’s main case.

A 7-pack multi-leaf equalizer spring took care of track vertical oscillation while the track frames themselves were supported by a shaft through the end of the tractors main case.

This was a bit of a weak spot in the HD-19 as wear in this area caused the track frames to go out of alignment unless the maintenance people were super vigilant.

The problem would be remedied in the later HD-20.

Final drives were double reduction and featured Timken tapered roller bearings throughout.

The Undercarriage

As for the tracks themselves, the HD-19 rode on a six-roller frame with spoke-type idlers, and two carrier rollers per side.

All of the rollers featured 1000 hour extended lubrication intervals thanks to Allis-Chalmers’ continuing development of Duo-Cone seal technology

Track tension was maintained by a bell crank arrangement and recoil spring.

The tracks themselves were 38-section with 24” single grouser shoes.

For the Operator

The Allis-Chalmers HD-19 featured an exceptionally clean deck for the time period and was easy to get on and off the machine.

Instruments were grouped in a small panel just to the right of the console which contained the two steering clutch levers and throttle control.

Gear change lever was centrally placed emerging from the floorboards with the master clutch on the operator’s left.

The only other controls were the two foot brake pedals.

A deep and comfortable seat cushion and back was provided for the operator.

The Attachments & Options

As Allis-Chalmers did not manufacture any of their own attachments during the time the HD-19 was in production, it was up to companies such as Baker, Garwood and Carco to outfit the machine for use.

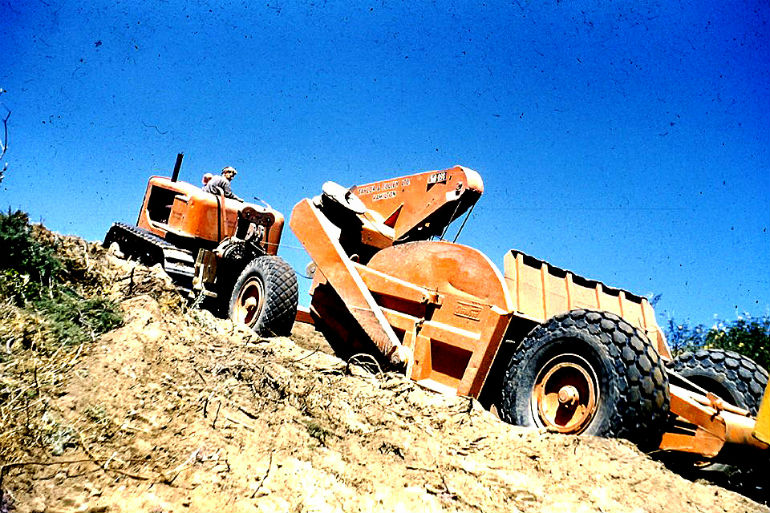

From published photographs it would seem that Baker was the major supplier of both cable and hydraulically operated bulldozers for the HD-19 while the scrapers most chosen for use behind the machine were Baker or Garwood.

Cable controls (PCUs) were supplied by Garwood, Heil and Buckeye and there are also examples known to have been fitted with with LeTourneau and Caterpillar PCU’s.

Although the occasional Hyster winch could be seen on an HD-19 equipped for logging, the vast majority of logging winches fitted to HD-19s were supplied by Carco.

Optional attachments offered by Allis-Chalmers itself included a cab with heater, engine hood, side screens and front bumper (mainly for logging applications), belly guards, track roller guards, and one must not forget the chassis-mounted front push plate applied to a lot of scraper towing machines.

End of the Line

The last Allis-Chalmers HD-19 came off the assembly line in 1950, and some 2600 machines of this type were produced.

For a short time it was the world’s largest and most powerful track type tractor until International-Harvester brought out its TD-24.

The HD-19 was replaced in production by the more powerful model HD-20 in 1951, but that is another story.

The New Zealand Connection

It is not known how many Allis-Chalmers HD-19s were imported into New Zealand but there certainly were several of them.

All records of Allis-Chalmers’ importations from that period have unfortunately been lost.

Last known user of the type was Ian A Martin Ltd who had at least two operational examples in the Thames region as late as 1982.

It is not always easy to spot the difference between an HD-19 and the similarly powered HD-15.

Both have the twin aircleaners on the right and the exhaust stack on the left.

However, careful examination of photos reveal the HD-19 is a physically larger tractor and has more operators deck room than an HD-15.

For the Model Collector

Unfortunately there are no known models in any scale of the Allis-Chalmers HD-19.

Models exist of its replacement, the HD-20, but if you want an HD-19 you will have to scratch build one.

Brief Specifications – Allis-Chalmers HD-19

Engine: General Motors 6-71. inline, 6-cylinder diesel rated at 163 flywheel horsepower at 1750 rpm

Clutch: 17” single plate, over-centre type made by Lipe-Rollway

Torque Converter: Allis-Chalmers own design, diesel fuel filled

Transmission: Allis-Chalmers constant mesh, 2-sp fwd, 1 rev.

Top Speed: 7 mph

Steering Clutches: Multi-Disc, hydraulically boosted

Brakes: Large contracting band type

Track Frame: 6-roller

Track Gauge: 84”

Std. Track Shoe: 24”

Length (bare): 15’ 8”

Width: (bare) 9’ 1¼”

Height: 8’ 8”

Op. Weight (bare): 20 tons