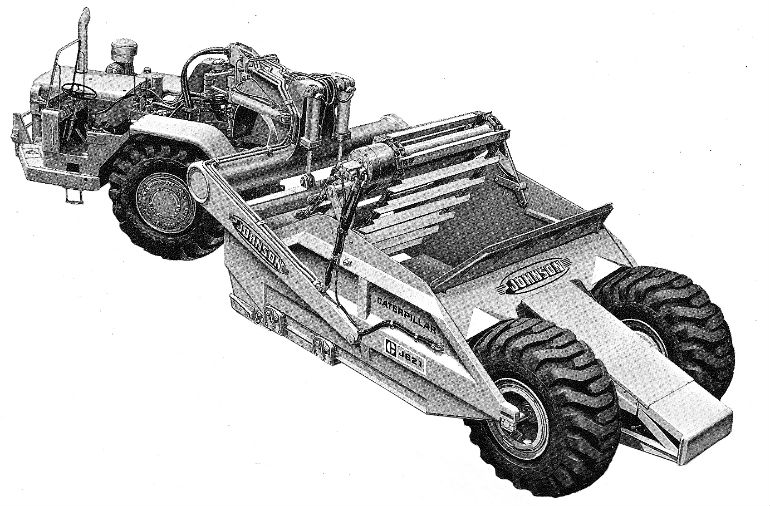

A logical development of the Caterpillar J619, Caterpillar’s J621 elevating scraper was introduced in 1965. By Richard Campbell

The Caterpillar J621 was a pairing of the tractor unit of the then new 621 open bowl scraper with an elevating scraper built by Johnson Manufacturing Co of Lubbock, Texas, which had also built the bowl for Caterpillar’s former J619 elevating scraper.

There is some debate over who exactly came up with the elevating scraper concept – Hancock or Johnson – as both companies were located in Lubbock, Texas. However it is generally accepted that it was Hancock that produced a practical prototype first and, indeed, were supplying scraper bowls to John Deere as early as 1957 for use with its model 840 agricultural tractor.

Caterpillar, which had been co-operating jointly with Johnson since 1964, had acquired the company lock, stock and elevators by 1971

J621 tractors were powered with a Caterpillar model D336TA V8 turbocharged and after-cooled diesel rated at 300 horsepower and connected to a Caterpillar eight-speed full powershift transmission, with the first two speed ranges direct converter drive for added heft during loading and pulling out of the cut.

Late production versions of the J621 featured the eight-speed, semi-automatic transmission (as fitted to other Caterpillar scrapers) for increased parts commonality.

The D336 engine was unusual in that it was a 60 degrees V8 and was only fitted to one other machine in the Caterpillar product line, the early model Cat 980 loader.

It made the most frightful sound during start up, almost as though it was about to throw a connecting rod through the side of the engine block – this sound was apparently normal.

Not the most reliable of Caterpillar’s engines, most long-term users eventually repowered the J621 with a Caterpillar 3306T or 3406T engine.

Your author knows of at least one machine fitted with a Detroit Diesel 8V-71!

Cushion Hitch was never offered for use with the J621 so the machine used the standard Caterpillar triangular hitch of the day, with two steering cylinders mounted high on the gooseneck.

These allowed 90 degree steering to either side of centre, unless the machine was fitted with a Roll Over Protective Structure (ROPS), which limited the steering angle to the left to about 70 degrees as the structure interfered with the scraper’s draft arms on that side.

A comfortable enough machine to operate, Cat J621s featured a full set of instrumentation on a split panel either side of the steering column.

Visibility to the left and straight ahead was good but somewhat restricted to the right by the large air cleaner precleaner assembly.

Bowl operation levers were to the operators right and the usual method of operation necessitated the operator looking over his right shoulder during loading and spreading.

The operator was provided with a deep cushion hydraulically snubbed seat, which was mounted over the front edge of the left hand wheel well. During the colder months a sliding panel on the side of the engine cover could be opened to provide heat to the operator’s legs and a windscreen was usually fitted as standard. Caterpillar never offered a cab as an option for the J621.

The Johnson 621 scraper was all-hydraulically operated and was rated at 21.5 cubic yards heaped.

The elevator featured 18 flights measuring six feet, six inches in length, driven by a two speed reversible hydraulic motor.

During ejection, which was a two stage process, the entire front floor including the cutting edge retracted back on outside hung rollers to about halfway, allowing the load to drop out, then the ejector bulldozed the remainder of the load out through the now cavernous opening, the retracted cutting edge acting as a strike off or leveling plate. Upon returning to the cut position the sliding floor was held in place by a hydraulic lock.

Four teeth could be fitted to the cutting edge to aid in breaking up and loading hard or cohesive soils.

A reasonably popular machine for Caterpillar, the J621 remained in production until 1972, when it was replaced by the improved model 623.

Its contemporaries included the Michigan 210H, Allis-Chalmers TS-260E and the wonderful Wabco 222F.

The NZ connection

Caterpillar dealer Gough, Gough & Hamer imported approximately nine J621s during the machine’s production run. These were delivered to mostly North Island contractors (although there were also a couple which went to the South Island).

Predominantly used in housing subdivisions and road realignment work, users included ID Loader of Wanganui; Harliwich Carrying Co, Otago; W Stevenson & Sons, Auckland; Green & McCahill, Auckland and Fletcher Construction of Wellington, which must have liked them as it had two.

There are still some examples left in operation.

Brief Specifications – Caterpillar J621

Engine: Caterpillar D336TA, turbocharged, aftercooled V8, 300 fwhp

Transmission: Caterpillar 8-speed barrel planetary powershift

Top Speed: 32.5 mph

Brakes: Expanding shoe on all wheels, sequenced to brake scraper first

Steering: Full hydraulic

Turning Circle: 37’ 8”

Capacity: 21.5 cubic yards

Elevator Flights: 18

Elevator Speed: 171 feet per minute (low), 262 feet per minute (high)

Length: 39’ 4”

Width: 11’ 9”

Height: 11’ 4”

Operating Weight: 28 tons (empty), 49.5 tons (loaded)